—

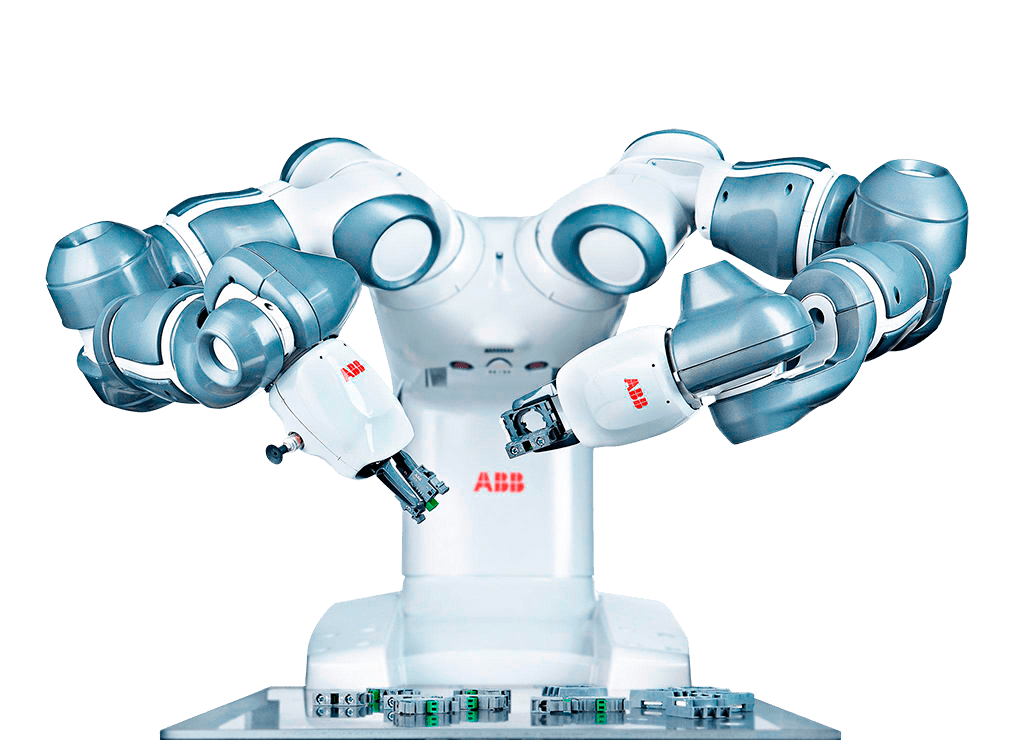

Automate your assembly process with cobots

Streamline operations, reduce costs and boost efficiency

Are you tired of the inefficiencies, lack of flexibility and high costs associated with traditional assembly processes?

ABB's adaptive robot are revolutionizing the manufacturing industry by seamlessly integrating with human workers to optimize assembly tasks. fill out the form, we will contact you soon!

Want to know more?

—

Why choose cobots for assembly?

—

1. Flexibility and adaptability

Cobots effortlessly adapt to a wide range of assembly tasks, eliminating the need for costly retooling or reprogramming. They can handle intricate operations with dexterity, precision and speed, allowing you to tackle diverse manufacturing challenges. With embedded force control capabilities, our cobots are able to adapt and react to different process conditions, always ensuring quality and productivity

—

2. Increased efficiency

By interacting when needed with human operators, cobots significantly increase overall productivity. Robotic assembly automation allow you to perform repetitive tasks with consistent accuracy, freeing up human resources to focus on more complex and value-added activities.

—

3. Improved safety

Designed to prioritize safety, cobots are able to detect human presence and impacts, allowing for safe and collaborative interactions when needed. Our force control cobot for assembly are engineered to minimize the risk of workplace accidents and promote a secure working environment.

—

4. Cost-effectiveness

Integrating robotic assembly automation into your process can lead to substantial cost savings. With their efficient operation and reduced downtime, cobots help optimize resource allocation and achieve a higher return on investment compared to traditional automation solutions.

—

5. Easy Integration

Our collaborative robot for assembly are designed to seamlessly integrate into your existing workflows. User-friendly interfaces and intuitive programming capabilities make it easy for operators to set up and modify tasks, without the need for extensive technical expertise or specialized training.

—

Embracing the future of assembly

Achieve a harmonious partnership between humans and cobots

The future of assembly lies in the collaboration between humans and cobots. These robotic assistants are not here to replace human workers but to augment their capabilities. Imagine a seamless partnership where humans and cobots work together to achieve new levels of efficiency and productivity. With cobots by your side, you can optimize your assembly process, leverage human creativity and allow robots to handle repetitive or physically demanding tasks.

Experience the future of manufacturing and embrace collaborative automation today.

—

Scale up your business with the support of our experts

ABB as the best assembly automation company, provides a personal, technical assistance to help you get started with cobots in your tasks

Don’t know where to start?

Our experts are here to answer your questions.

Thanks to this unprecedented degree of collaboration, you will experience a boost in productivity and efficiency and, ultimately, in competitiveness.

—

Simplifying setup with intuitive software

Seamlessly integrate cobots into your assembly workflow

Setting up a cobot for assembly has never been easier. Thanks to advanced software interfaces, the integration process is smooth and hassle-free. With intuitive programming tools and user-friendly interfaces, you can quickly train your cobot to perform specific assembly tasks. Take control of your assembly operations without the need for extensive programming knowledge. Seamlessly transition to cobot automation and witness the transformation of your assembly processes. Embrace simplicity and unlock the full potential of your assembly operations.