—

Increase productivity and flexibility with our machine tending solutions

Are you looking for ways to automate, optimize, and reduce costs in your machine tending application?

Your search ends here! Our easy-to-use solutions are designed to increase productivity and improve efficiency smoothly.

Fill out the form on this page to get in touch with us at ABB Robotics and take a step closer to an efficient machine tending solution!

—

Increase your machine utilization

—

1. The easiest way to automate

Quick and easy integration into your production line ensures an uninterrupted workflow. Our robots and cobots have precise movements and can be easily programmed by operators. They also integrate smoothly with peripheral equipment and machines.

—

2. Maximize your results

Automate machine tending processes and take advantage of our class-leading repeatability, speed, and precision. Accelerate production while giving your employees more time for value-creating activities.

—

3. Increased safety

We are proud to create safer workplaces. Our automation solutions, including both traditional industrial robots and collaborative robots, are designed to reduce the risks associated with manual labor. By using our solutions, we can promote a safe working environment and reduce the risk of accidents and injuries, whether the robots work independently or alongside operators.

—

4. Intelligent adaptability

Our automation solutions are highly versatile and can perform a range of tasks. Together with various accessories and software, our robots and cobots smoothly adapt to different tasks and requirements.

—

5. Cost-effectiveness

By automating machine tending tasks, you can optimize workflow, reduce the risk of defects, and achieve long-term cost savings. Our cobots contribute to a faster return on investment and ensure a smoother and more productive operation.

—

We have solutions for all machine service needs

—

FlexLoader™ SC 3000

An advanced automation solution for machine tending that can increase machine utilization by up to 60 percent and reduce operating costs. It is modular and easy to use, with installation in one day and the possibility of unattended operation for several hours. This leads to a quick return on investment and a sustainable competitive advantage.

—

Robot Guiding Vision System

An advanced vision system that guides ABB’s industrial robots in material handling. The system offers high speed, short learning times, and reliable production. FlexLoader Vision handles workpieces of various sizes and complex shapes without mechanical fixtures, reducing costs and complexity. Easy learning of new workpieces in less than 10 minutes.

—

FlexLoader™ FP 800

A compact automation package for machine tending, consisting of a robot, control system, camera tower, and podium. It picks workpieces directly from the pallet and can be adapted to various processes such as pallet handling and quality control. The system is easy to use, requires no special fixtures, and reduces operator time by up to 90 percent. Learning time for new workpieces is less than 10 minutes.

—

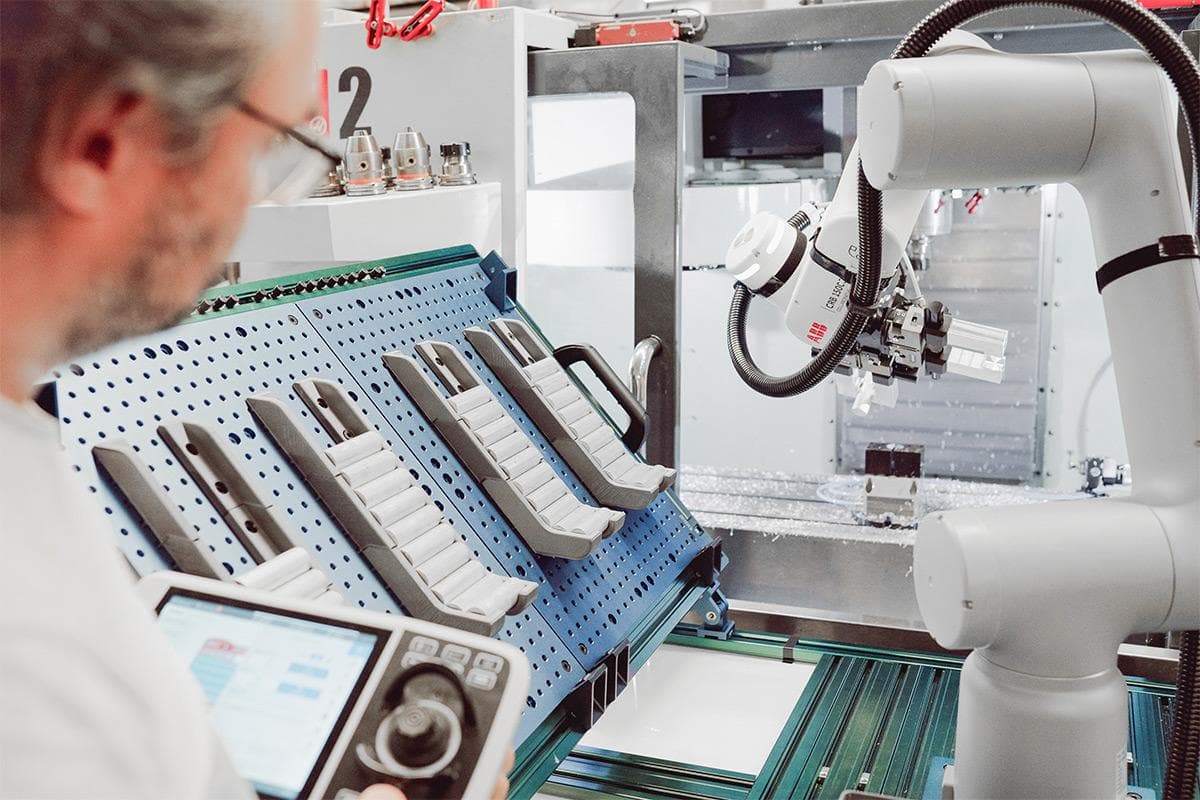

OmniVance™ Cobot Machine Tending Cell

A fully integrated collaborative machine tending cell that simplifies automation. It combines a collaborative GoFa™ 12 robot and user-friendly software in a compact solution for quick installation and easy use. The OmniVance™ cell can reduce repetitive machine tending tasks by up to 60%, freeing workers for more value-creating tasks.

—

Experience seamless collaboration between humans and cobots

Automation is for everyone

Experience effective collaboration between humans and robots with our cobots.

Improve precision, increase efficiency, and promote growth, regardless of the size of your business.

The future of machine tending is here, and it is built on collaboration.

—

Discover intelligent automation

Improve manufacturing quality

Experience the future of manufacturing with our cobots. With built-in sensors and cutting-edge vision systems, they can detect collisions and quickly adapt to changes for efficient operation. Step into a new era of automated machine tending!

—

Effortless software for maximizing your investment (ROI)

Streamline your operations with intuitive software

Setting up cobots for machine tending is easier than ever.

Our dedicated machine tending software streamlines the configuration process, allowing you to quickly program the cobot without complex coding and specialised training.

The user-friendly interface guides you through the setup, empowering employees with no programming background to become proficient in no time.

Simplify your business and get the most out of your investment.