—

Transform your palletizing process

Streamline, automate and reduce costs with pioneering cobot palletizing solutions

Are you seeking ways to optimize your palletizing processes?

You can achieve seamless palletizing workflows, improving productivity and reducing musculoskeletal disorders, by combining human expertise with the precision and efficiency of cobots.

Want to know more?

—

Why choose our cobot for palletizing?

—

1. Increased efficiency

Boost productivity with faster palletizing cycles. Experience unparalleled productivity gains as our high speed robot palletizer solution accelerates palletizing cycles, enabling faster throughput and maximizing your operational efficiency.

—

2. Enhanced safety

Ensure a secure work environment with built-in safety features. Prioritize workplace safety with our cobots' comprehensive safety features. Designed to minimize risks and hazards, our cobots create a secure work environment with built in and external sensor systems.

—

3. Adaptability

Easily adapt to changing palletizing needs and configurations. Embrace the versatility of our cobots, as they seamlessly adapt to evolving palletizing needs and configurations. Easily switch between different new packaging designs, multiple pack sizes and product variants and batch manufacturing.

—

4. Plug-and-play

Integrate accessories and peripherals into your cobot system and enhance its capabilities with advanced palletizing functionalities. Streamline your warehouse operations, increase productivity and reduce manual labor with this user-friendly and compact solution.

—

5. Cost savings

Optimize resources, minimize downtime and cut operational costs. Our robotic palletizer help you save costs, improve efficiency and ultimately enhance your bottom line.

—

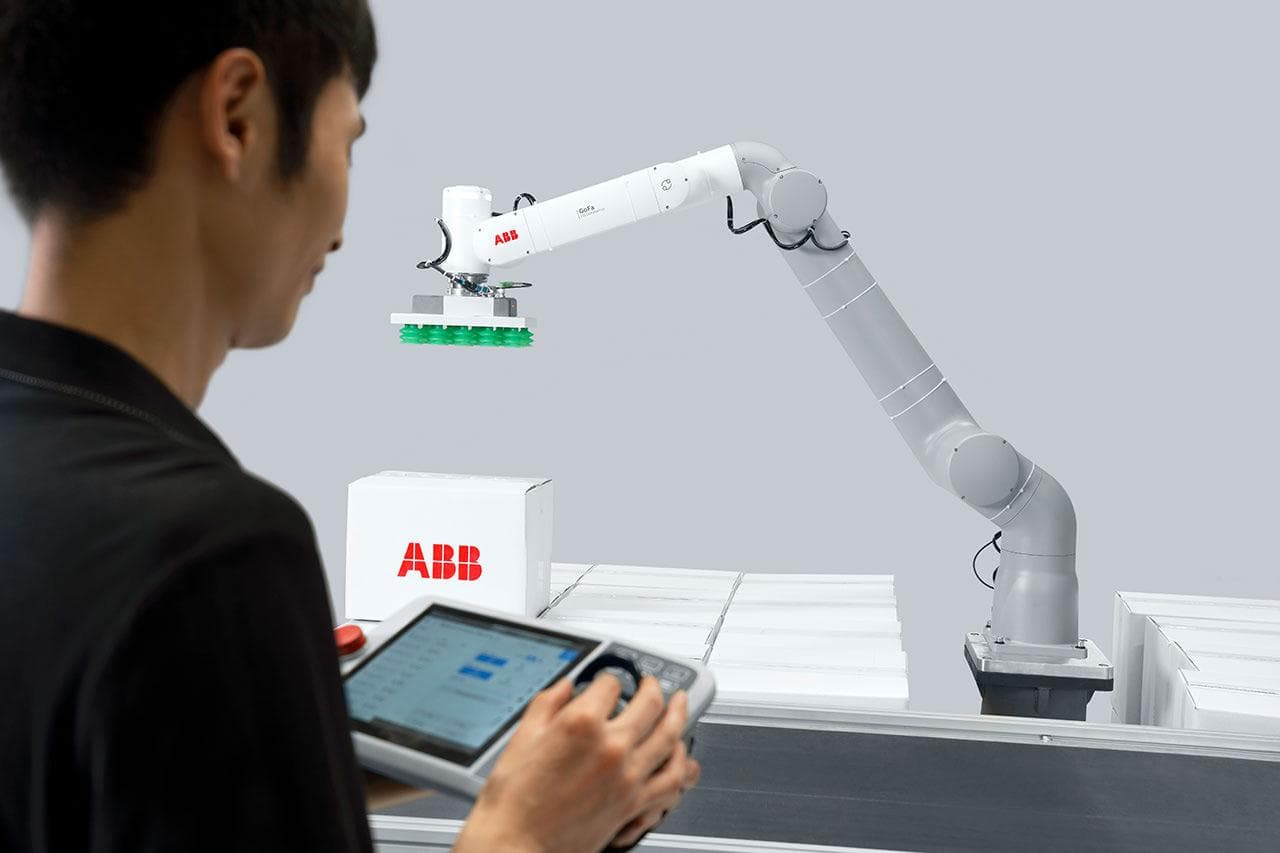

The power of collaboration: humans and cobots united

Enter a new era of efficient collaborative robot palletizer workflows

Our cobots are designed to assist and augment human workers, taking care of repetitive, physically demanding tasks while ensuring human oversight and expertise. This collaboration improves efficiency and output and promotes a safer and more engaging work environment, where human workers can focus on more complex and value-added activities.

—

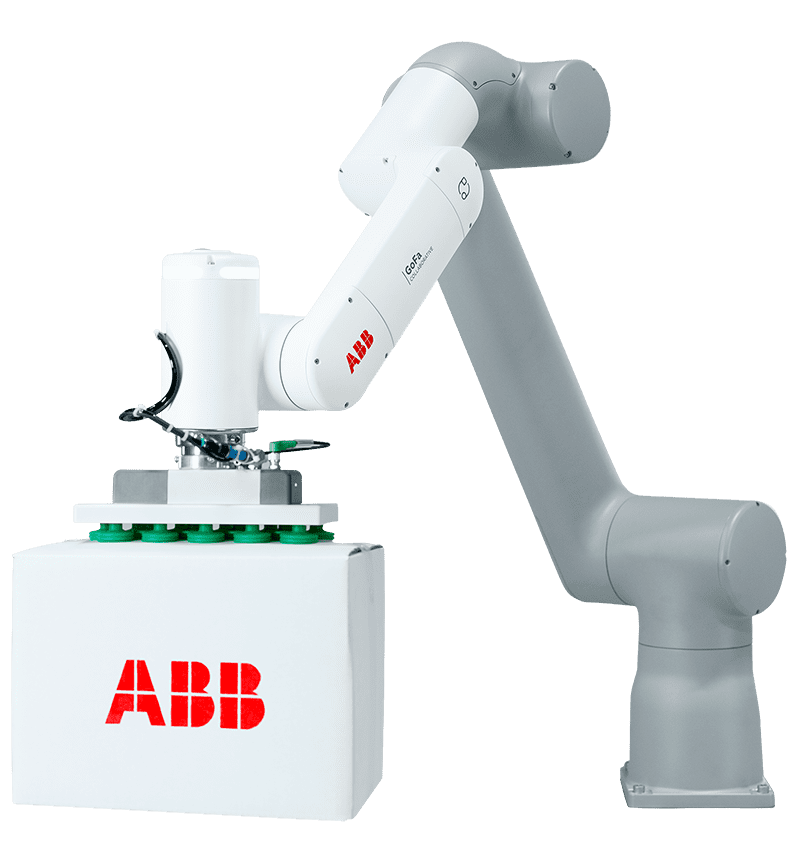

Intelligent palletizing at your fingertips

Empowering efficiency and precision in every move with collaborative robot palletizing

Our latest-generation palletizing cobots take automation to an entirely new level: from picking up boxes and items of various shapes and sizes to performing flexible adjustments. For instance, the innovative GoFa™️ model ensures precise and consistent movements and is capable of reaching extensive work areas thanks to the widest range of motion in its category.

—

Simple setup, maximum potential

Streamline your operations with user-friendly cobot software

Setting up a cobot for palletizing has never been easier. Our intuitive Wizard software interface empowers you to configure and program ABB cobots with minimal effort. Whether you're a seasoned automation expert or a beginner, our user-friendly software ensures a smooth and hassle-free setup process. With drag-and-drop functionality, customizable workflows and comprehensive support, you can quickly adapt our cobots to your specific palletizing needs. Accommodate different product types, sizes or configurations.