—

ABB cobots: sanding and polishing made easy

Increase efficiency, improve quality and reduce costs today.

CONTACT US—

Why choose collaborative robots for sanding and polishing?

—

1. Precise results

Sanding and polishing operations require precision and constant pressure throughout the process. By automating processes using ABB cobots, you can improve process speed while reducing errors and inaccuracies.

—

2. Increased safety

With their sensors and safety software, cobots are designed to work with operators. By automating sanding and polishing tasks, you can reduce the risk of injury from repetitive work and exposure to harmful dust and chemicals. Enjoy peace of mind knowing your workers are protected.

—

3. Increased efficiency

Our cobots can significantly increase sanding and polishing efficiency. Because of their speed and accuracy, they can complete tasks in a fraction of the time compared to manual work, enabling you to achieve higher results and meet challenging production goals, all with fewer errors.

—

4. Cost savings

By automating sanding and polishing processes with cobots, you can realize significant cost savings. Reduce labor costs and minimize material waste caused by human error. With increased efficiency and productivity, you can optimize resource allocation and achieve better profitability.

—

5. Flexibility and adaptability

ABB cobots can be easily programmed to handle a wide range of sanding and polishing tasks, adapting to different materials, shapes and sizes. Suitable for complex surfaces, our cobots can keep constant pressure thanks to arm-integrated sensors.

—

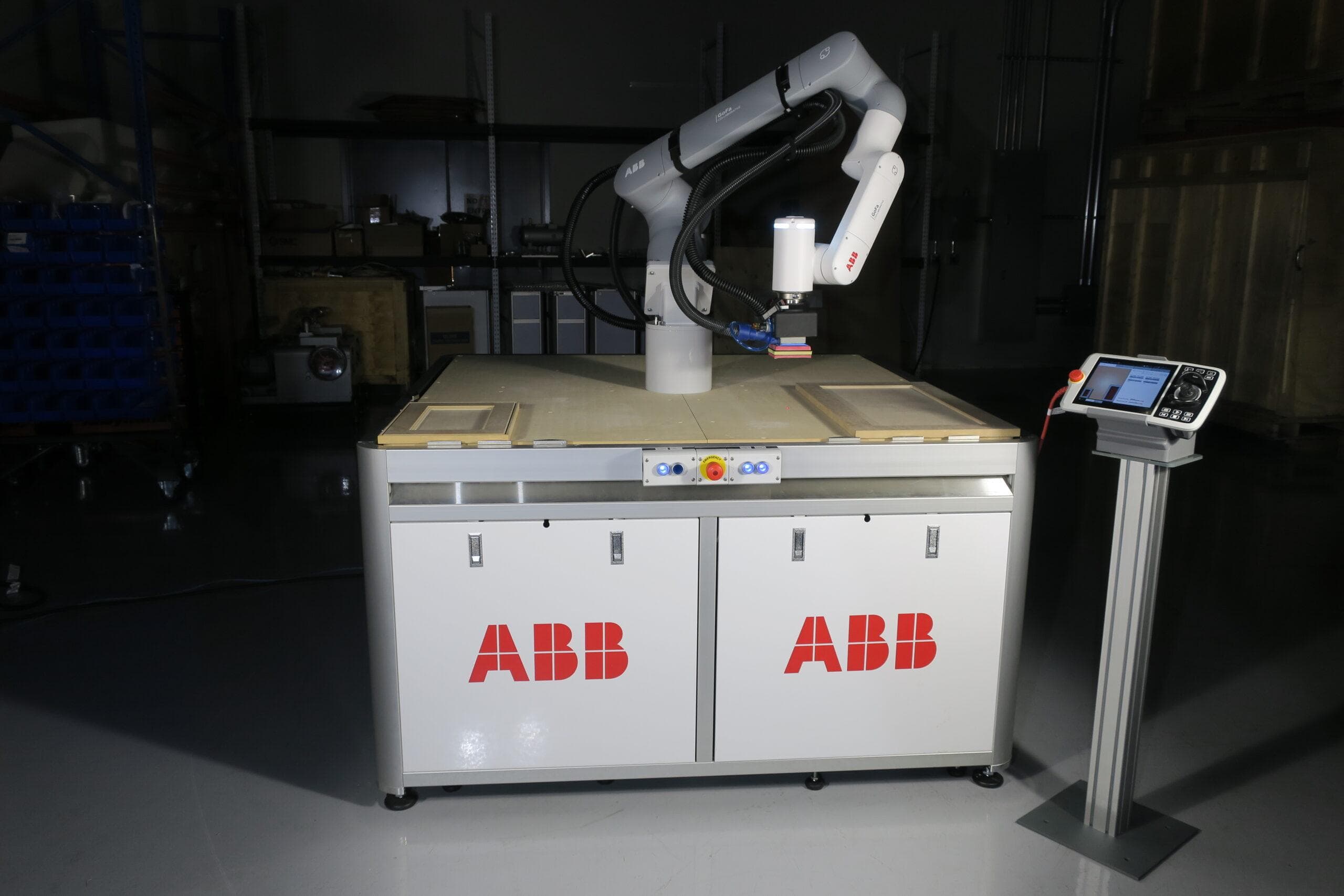

More speed and higher output with cabinet sanding cobots

Get unparalleled precision and efficiency.

We have partnered with Cobot Intelligence to provide customers with a Cabinet Door Sanding Solution fitted with an ABB GoFa. The cobot is equipped with sensors to determine sizing of the cabinet door in real time and auto-generate the sanding path. An incredible innovation that cuts sanding time in half allowing users to double production. Commissioning and training is performed on customer site and cells can be activated on the floor with in 1-2 days.

—

We support you step by step

Interested in automation but not sure where to start?

Book a free consultation with our cobot experts to see if ABB cobots are really right for your company. Our qualified experts will guide you through all the variables and questions involved in selecting and implementing collaborative robotics.

—

Simple configuration and seamless integration

Simplify your operations with intuitive software

Configuring a cobot for sanding and polishing has never been easier! Our intuitive Wizard software interface empowers you to configure and program ABB cobots with minimal effort. No in-depth coding or specialized training is required.