—

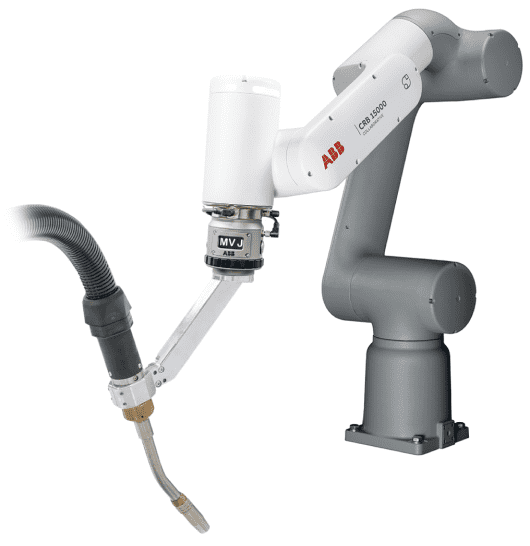

GoFa™: welding made simple

Automate your welding tasks with an easy-to-use ABB cobot.

Are you facing periods of seasonal work peaks and thinking about how to increase production with robotic automation?

Do you want your employees to have time to tackle more value-add activities?

Is it difficult to find skilled welders?

Do you want to improve quality, keeping the same flexibility as with manual welding?

The answer is GoFa™ CRB 15000.

Want to know more?

—

5 advantages of choosing GoFa CRB 15000 for Arc Welding

—

1. Safety

Modern robots are moving out of their cages to work closer with human coworkers, opening new opportunities for flexible automation. ABB cobots enable fenceless installation, including a comprehensive safety functions toolbox with safe speed, safe force and safe position.

—

2. Productivity (ROI)

Upgrade your production capacity starting today. You can increase productivity and quality for your welding process, thanks to GoFa's fast setup and performance. GoFa is easy to integrate into existing production lines and makes automation of smaller production batches cost-effective. Save up to 70% of programming time with the Easy Teach Device - an auto-generated programming feature.

—

3. Ease of use

ABB's GoFa is a best-in-class, lightweight cobot that's user-friendly with intuitive configuration through apps on the FlexPendant. Smooth cobot programming, hand-guided movement, and the Easy Teach Device enable non-experts to create welding programs effortlessly, promoting real flexible production.

—

4. Flexibility

GoFa works for a large variety of applications. Easy to be re-programmed, it's perfect also for SMEs with high-mix low volumes. It employs smaller, leaner installations that can be easily moved around. The GoFa design is focused on minimizing its footprint and weight while maximizing speed and reach, to provide the highest levels of flexibility.

—

5. Quality

Welders can reduce scrap in production compared to manual operations and benefit from a superior path accuracy for high quality welding. The welding process is managed by Arcware, our proprietary software, used by thousands of customers worldwide and validated by decades of experience. Upskill existing manual work now!

—

When humans and robots collaborate

Discover GoFa™ CRB 15000

GoFa is designed to help businesses ‘go further and do more’ with a robotic helping arm.

Join other SMEs and larger companies that have already enabled easy automation without the need for in-depth programming skills.

GoFa’s features allow it to be used alongside human workers and with compact footprint. Robot and human now can cooperate on the same tasks, without compromising productivity or safety.

This generation of robots is enabling more and more businesses to automate repetitive and dangerous processes, to enhance productivity and flexibility while leaving employees free to do more value-add activities.

—

Scale up your business with support from our experts

ABB provides a personal, technical assistance to help you get started with GoFa in your welding tasks.

Interested in GoFa but don’t know how to start?

Our experts are here to support you. Get a boost in productivity and efficiency - and, ultimately, in competitiveness.

—

Cobot Arc Welding Package

Complex welding at the touch of a button.

The Cobot Arc Welding Package is a breakthrough solution that dramatically simplifies creating and executing welding sequences. The main innovation is the Easy Teach Device which uses lead-through programming and interactive buttons to determine weld points.

The Cobot Arc Welding package has been developed to reduce the complexity of robotic welding and lower the barriers to automation for SMEs and first-time users such as manual welders. Fit on ABB’s award-winning GoFa Cobot, the Cobot ArcWelding Package is the first of its kind to enable users to program a robot without using a teach pendant.

With the ability to cut down programming time by about 70%, the Cobot Arc Welding Package is a game changer for the global welding market.