—

Enhance your manufacturing process with cobots

Are you looking to automate your manufacturing processes and achieve greater efficiency in your operations?

Contact us and speak to a cobot expert.

—

Why choose ABB cobots?

Our collaborative robots are designed to seamlessly integrate with your workforce, enhancing productivity and tackling your toughest production challenges. Experience how ABB cobots are revolutionizing industries worldwide with their advanced capabilities.

Increased productivity

Boost output and speed up cycle times with ABB collaborative robots working alongside your employees, amplifying their capabilities and accelerating tasks.

Enhanced safety

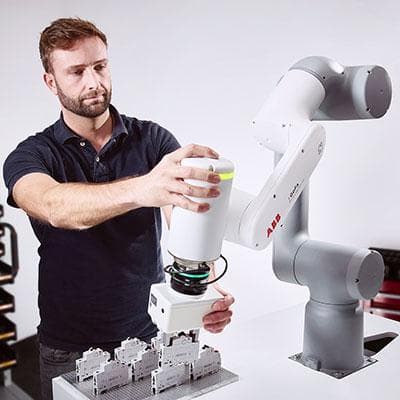

Prioritizing safety with built-in sensors and intelligent algorithms, ABB cobots detect and respond to human presence, significantly reducing accident risks.

Easy programming

User-friendly and intuitive, ABB collaborative robots can be programmed and easily managed by operators, empowering them with new skills and without the need of extensive training.

Flexibility and adaptability

Adaptable to a wide range of tasks, ABB cobots bring versatility to your operations, from assembly to machine tending, meeting your changing production needs.

Cost efficiency

Offering cost-effective automation solutions, ABB cobots require minimal infrastructure changes, have low energy consumption, and deliver a rapid return on investment.

—

A cobot for every team

Discover our comprehensive solutions, including software and services, to support your automation journey.

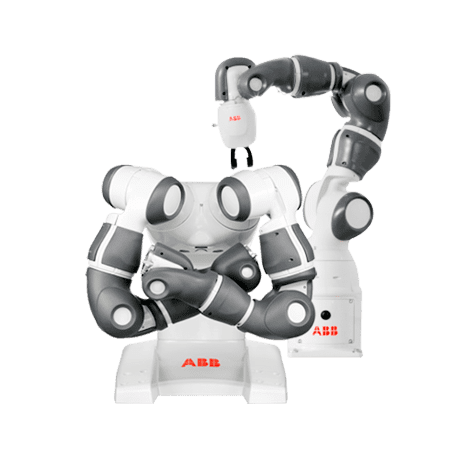

YuMi®

Payload

0.5 kg

Degrees of freedom

7

Reach

559 mm

Max TCP Speed

1.5 m/s

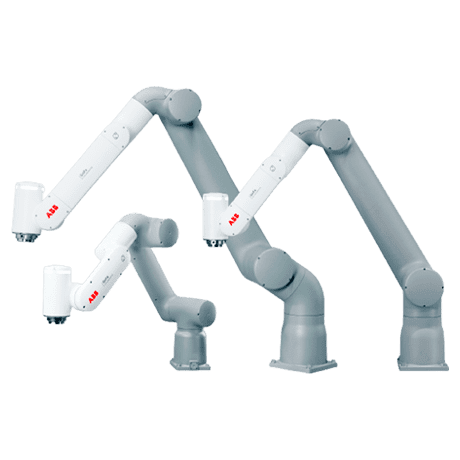

GoFa™

Payload

Up to 14 kg*

Degrees of freedom

6

Reach

Up to 1620 mm

Max TCP Speed

Up to 2.2 m/s

*Wrist down configuration

—

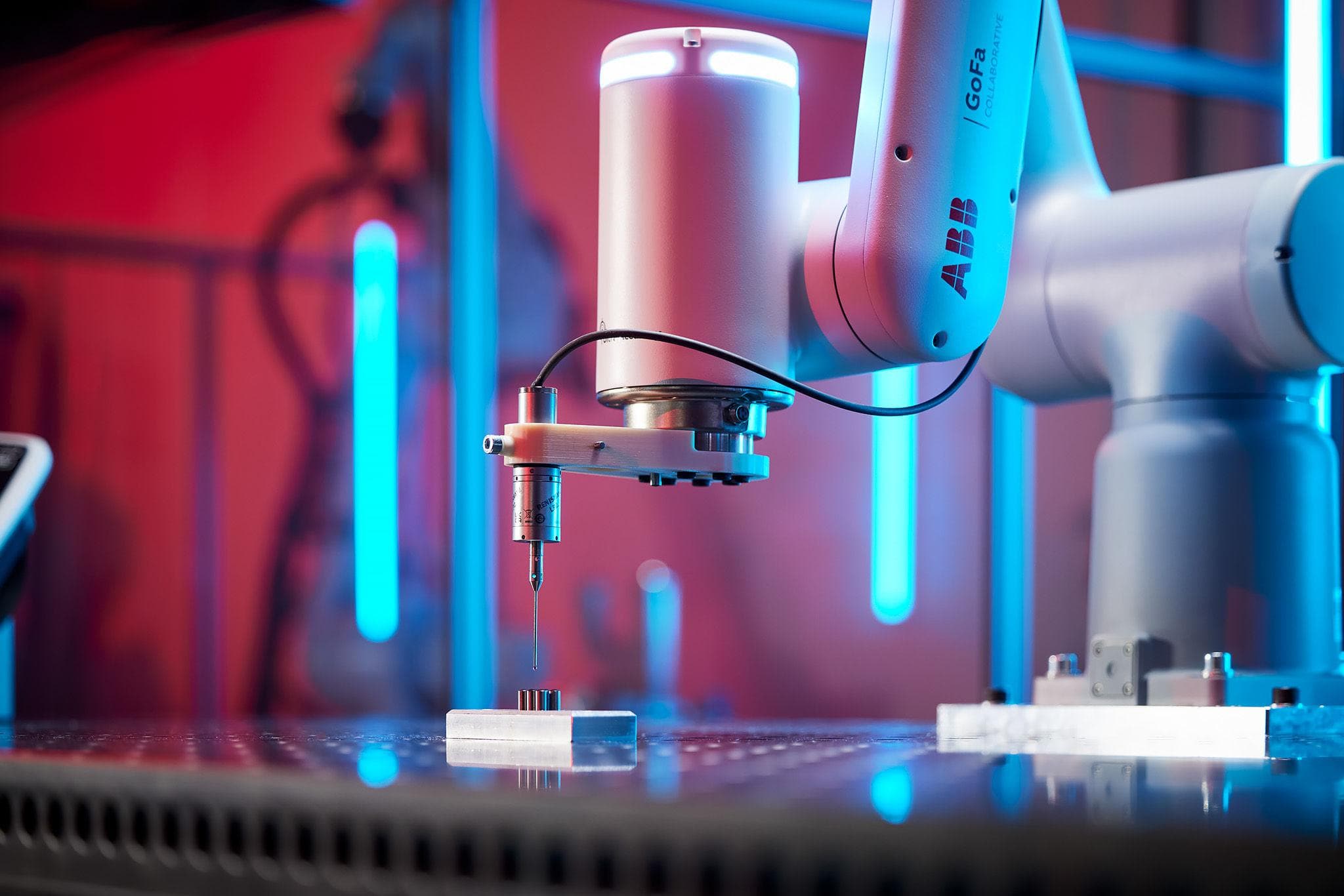

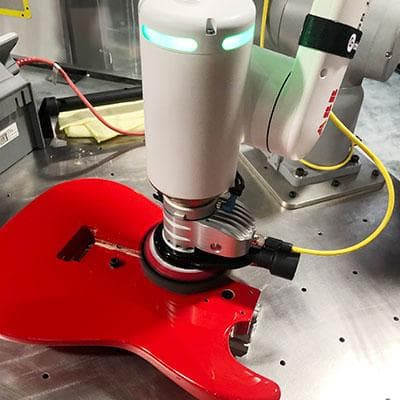

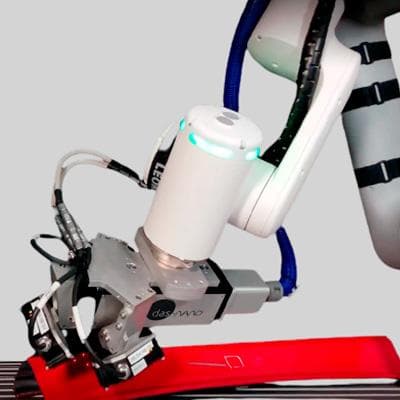

Adding Ultra Accuracy to GoFa

Adding the Ultra Accuracy feature makes GoFa the most path-accurate cobot on the market, offering 10 times greater precision than other cobots, and setting a new standard in accuracy. This superior performance meets the demands of applications where exact positioning is crucial for maintaining product quality and operational efficiency.

—

Embracing collaborative robotics

Working hand to hand towards success

ABB YuMi, ABB GoFa and ABB SWIFTI seamlessly integrate into dynamic work environments. Their versatile design, with optimized payload capacity, degrees of freedom and expansive reach, enables precise and adaptable task execution. The impressive max TCP speed ensures swift and accurate responses, showcasing a harmonious blend of innovation and functionality for operational excellence in various applications and industrial settings.

Welding

Cobots revolutionize welding processes, ensuring precise and efficient fabrication.

Machine Tending

Cobots optimize machine tending, enhancing production efficiency and safety.

Assembly / Screwdriving

Cobots streamline assembly lines, ensuring efficient and precise manufacturing.

Sanding and Polishing

In sanding and polishing, cobots ensure meticulous finishing with precision and consistency.

Palletizing / Packing

Cobots, they assist you in moving even the heaviest goods, organizing and stacking with precision.

Educational

In education, cobots foster interactive learning and technological engagement.

Gluing / Sealing / Painting

The cobots improve your craftsmanship ensuring that every detail is a masterpiece.

Handling / Pick and Place

The cobot will be your trusted companion for your everyday practices.

Testing / Inspection and Quality Control

Cobots excel in inspection, ensuring high-quality and consistent product standards.